Kaizen: 5 Pronciples to ensure the succes of the Japanese management model

The Japanese did not jump from job to job in search of the perfect, they can work from anywhere in the end to do the job of their dreams. Because it's all about the approach.

The Japanese have always been, are and will be very consistent. Even if you work as a janitor, you should not complain about destiny, but must bring their skills to perfection. Why again do not learn from the Japanese and try to control their method that they use in their management, applying it not only to work but also to yourself?

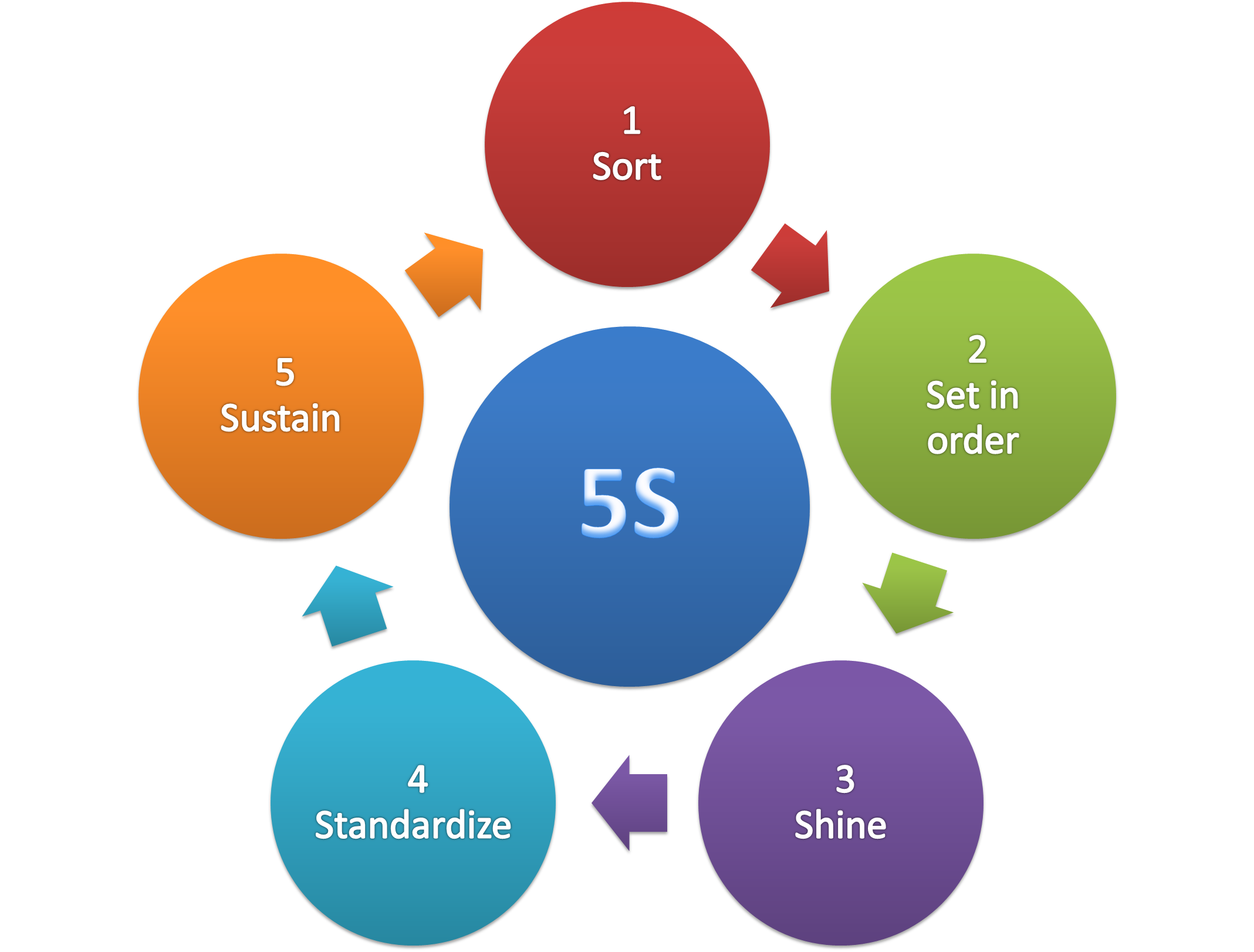

The basis of Kaizen method consists of 5 key elements, "5 S»:

- Seiri - tidiness - You need to sit down, to think well and make a list of what you want to improve, and what do you think prevents to work more efficiently.

- Seiton - order - After you drop all the excess, you can streamline the process of work, building things in the correct order. It will be good if you will keep things like your desktop diary at least the first few weeks, which will be made to record the case, the time at which they were carried out, the amount of time it took to execute them and celebrate their priority.

- Seiso - cleanliness - After the end of the day do not forget to clean your office desk and putting everything in its place. To find the right things and documents is much easier when everything is where it should be.

- Seiketsu - standardizing - Once you get rid of affairs, the implementation of which is not part of your duties, have built their workflow and break it down, not only in the workplace but also in your head, it's time to make this system. That is, every morning you have to follow all of the constructed scheme. Follow it, and you will see the results.

- Shitsuke - discipline - When the first 4 of the process are carried out, they become for you a new way of working. You must adhere to the intended path and not to retreat back to old habits and practices.

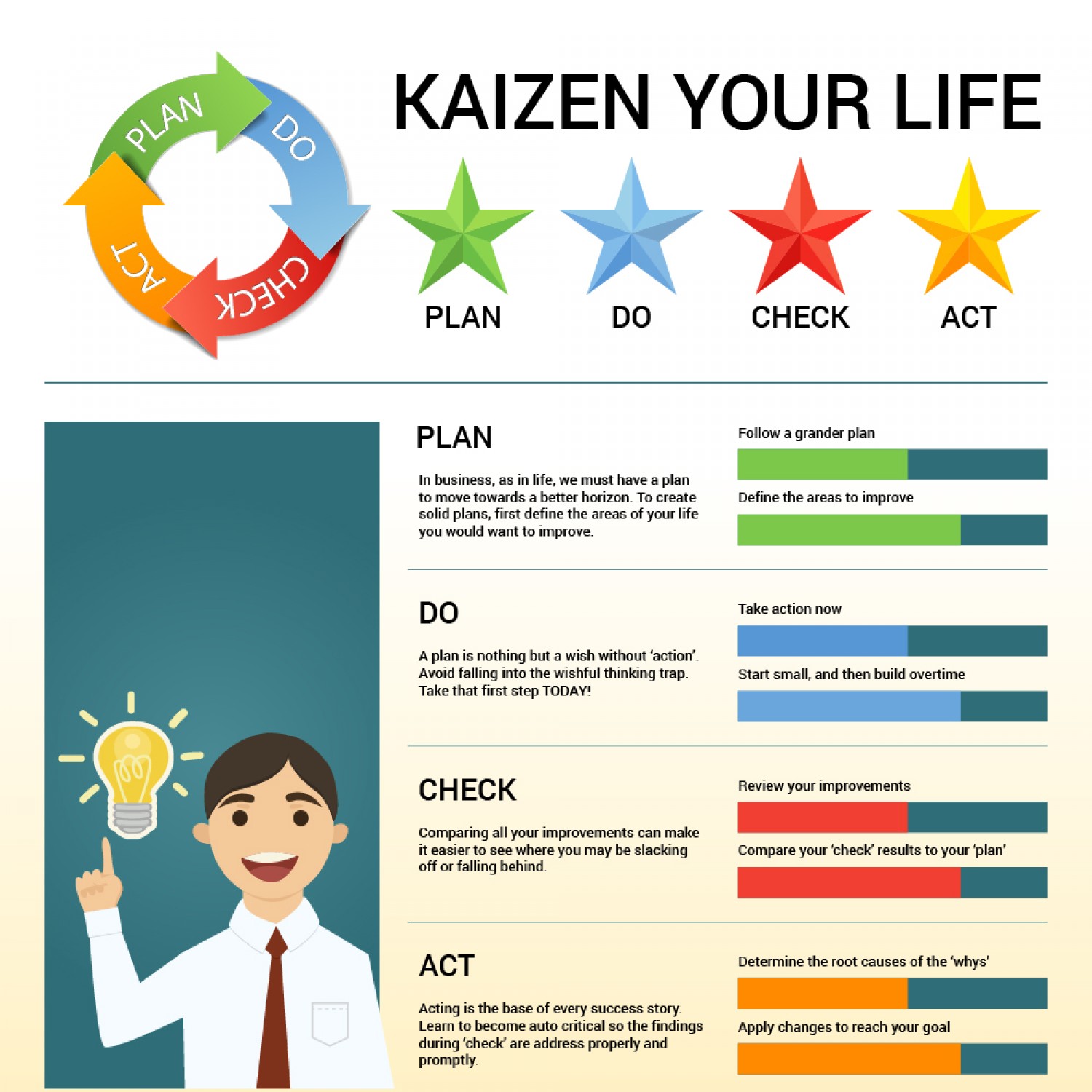

Thinking about a new method, you are likely going to think about what other changes can be made to improve efficiency. And so you will again review the first 4 steps, making adjustments to the process. So you constantly are improving the methods of work. And it - the right way, because the main objective of Kaizen is a constant, unceasing perfection.

These principles can be adjusted both for your work and for your life. After the Second World War thanks to the use of this technique to many Japanese companies, including Toyota, was able to quickly recover and catch up on the lost power. The main thing to observe the basic rules - to get rid of the unnecessary, to build the system and constantly improve it!

Have a nice week,

Your Ardas Team