Order Management System Development

Sooner or later, any successful business increases the flow of orders. Order processing is becoming more labor intensive, and the order management system needs to be improved.

The order processing system allows you to solve many different issues that have arisen in connection with the growth in sales.

In the article, we will consider why an order management system is needed, what the order system consists of, and how to create your order management system.

We will also view possible extensions to make such a system more efficient and user-friendly.

Types of Order Management Systems

The order management system provides structure and automation for processing company orders. Often, it is used as a part of transportation software development. It is an electronic system that receives information from a customer placing an order through an online resource, an employee entering a sale into a processing system, or other forms of placing an order within an organization. The system processes information according to predefined rules launches tasks or alerts the appropriate employees.

These systems can perform various organizational functions to increase efficiency and productivity in receiving and processing orders. A company can purchase a fully formed order management system, order an individual one, or develop its system.

Multiple organizational departments can use an order management system to improve collaboration and streamline the order fulfillment process. Most often, systems are divided into the following types.

Retail Fulfillment Suite

The retail fulfillment suite is a set of fully integrated solutions that can be implemented standalone or combined, depending on a retailer’s needs. Whether you’re a specialty or big-box retailer, a wholesale brand with stores, or a DTC, you need an integrated suite of solutions that includes an OMS, e-commerce warehouse management system (WMS), transportation management system (TMS), and micro-fulfillment center (MFC) capabilities.

These connected systems will enable you to respond to unique fulfillment challenges and help you manage and optimize the omnichannel experience from click to customer. The battle for retail supremacy is fought in the supply chain, and you need a supply chain OMS to help win that battle.

The Bundled OMS

A saying goes, “Don’t put all your eggs in one basket,” and with a bundled OMS system, that’s precisely what you’re doing. This type of OMS is offered as an additional ECP, ERP, or POS module. As with bundled, you’re not getting an optimal OMS solution. It’s designed for the vendor to entice you into thinking you’re getting more for your buck. Key selling points could be quick integration, single billing, and a one-stop shop.

However, out-of-the-box integrations/connectors and REST APIs have become standard issues, so the argument for rapid integration loses steam quickly. This solution is less robust than a true OMS, and the functionality typically exceeds expectations.

The Enterprise Solution

Traditionally, this extensive, bloated system requires a big, bloated IT team to run the technology. You might have one of those original on-prem enterprise OMS running right now, and the vendor might even be trying to get you to switch to its SaaS offering. Before “upgrading” and making a decision you might regret, you must do a proper needs analysis. Is this vendor giving you what you need (i.e., solving your complex problems, addressing your needs in their product roadmap, etc.), or are there alternatives that can provide better time to value and ROI based on your requirements?

Start-up Best-of-Breed

This type of OMS is all about order management … but that’s it. This means the OMS is missing a vital piece of the functionality you need in today’s omnichannel world — fulfillment. Fulfillment is everything, remember? Not to mention, a best-of-breed OMS tends to be VC-backed SaaS or private companies, where your system goes dark if the funding runs out. You might consider peaking at their balance sheet before committing to a contract.

Build Your Own Order Management System

Finally, the OMS is built by your IT team or a third-party developer. The trouble with this type of OMS — beyond the upfront investment and continual maintenance costs — is that the system is created based on current supply chain processes and models. While other retail systems (i.e., retail planning software) can run for years with the same logic, order management is different because it constantly evolves. It must continually be refined.

What happens when your fulfillment becomes more complex? It’s back to development to add additional functionality to solve additional complexity. You can simply turn on that functionality with a configurable OMS when needed.

Benefits of Custom OMS

If you plan to use an order management system in your company, it is helpful to understand how it can benefit your company. Key benefits of using an order management system include:

Efficient warehousing

The information provided by an order management system and its increased efficiency can be combined to improve the efficiency of your warehouse. An order management system can help you understand the speed of sales and processing of various products, which you can use to adjust inventory levels. By finding the lowest possible inventory levels for each product without being sold out and the order cannot be processed, you reduce the storage space required for each development and the inventory costs of storing those products.

Improved customer service

By making your order processing system more efficient, you can improve your customer experience. Effective order management can help improve lead times and reduce order fulfillment errors. This can result in customers receiving their items faster, making for a more customer-friendly experience and making them more likely to purchase from your business again.

Enhanced performance

Order management systems can help make order fulfillment employees more productive. The information provided by the order management system can bring clarity to employees. For example, being alerted when an employee has a new duty on order can help them complete their tasks on time so that other employees can focus on their responsibilities. This lets employees focus on doing their jobs rather than managing multiple responsibilities simultaneously.

Increased responsiveness

Because order management systems make tracking metrics throughout the order fulfillment process easier, they can also help you respond faster.

By analyzing metrics, you can identify areas where your order management system is performing correctly and where there is room for improvement. This can help you make your order processing more efficient to serve your customers better.

Key Features of Order Management Software

There is a whole range of order management features that contemporary order management software offers, as follows:

Order Creation & Processing

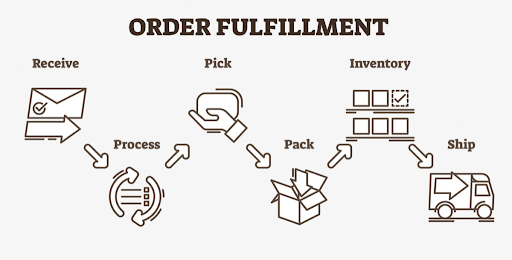

Order fulfillment is the process of processing an order and delivering it to customers. An order management system can use an automatically generated mechanized product search to prepare products for shipment. It can also notify a sourcing person, such as warehouse staff, to alert them to purchase so they can receive and process the order.

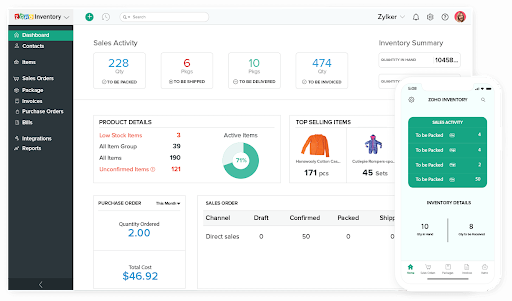

Inventory Management

The organization that an order management system provides can help a company manage inventory and maintain inventory levels. The system can automate purchase orders at a given inventory level, or trigger employee notifications when the company needs new purchases. Efficient warehousing ensures that a company has products available to deliver to customers when they place orders while minimizing the amount of inventory left in stock to reduce overhead costs.

Shipment Management

Tracking orders as the company receives them and moves them through the shipping process is a key component of effective order management. We explained it more in our article on how to build courier management system.

The order management system creates a structure for receiving new orders to notify any relevant parties of the order and they must do so to process it on time. This helps ensure that the company considers all orders to avoid oversights. Also, you might consider developing shipment tracking software separately from OMS and then integrating them with each other.

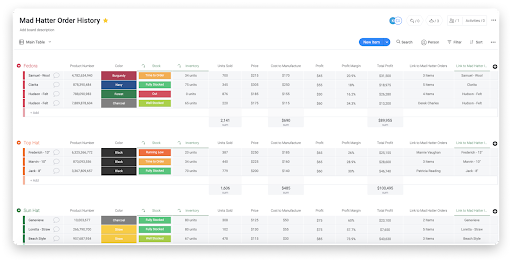

Analytics & Reporting

Creating and analyzing performance reports within an organization can be an effective way to improve productivity. Order management systems that track orders through every process step can help you quickly generate more detailed reports. Many order management systems can generate reports and charts based on parameters the user enters, such as average processing time or total orders processed, sorted by day, accessing the information already in the system from each order processed to create an accurate report.

Return & Refund Management

The order management system may include return management capabilities to improve the efficiency of return processing. This can notify personnel handling any customer returns of the return and alert them to any steps required to complete the return for the customer. This can save staff time and improve customer service during the return process. The order processing system can also provide return data, which allows the company to analyze and identify areas for improvement.

Customer Support

No matter how well the system is developed, failures always occur, or some functions may not meet the needs of a particular client, so any order management system must consider the presence of a customer support function by company personnel.

Important Integrations for OMS

Everyone would prefer to have all Order Management System (OMS) functionality in a single system. It eliminates programming and support costs and reduces the need to deal with multiple vendors and potential data problems. Whether that’s possible depends on your requirements and the size and complexity of your company. We find that even the smallest companies often have some interfaces.

An interface allows you to move data between one or more systems in one or more directions. Think of an interface or integration as a pipe or the conduit to move data. Usually, the OMS becomes the record system, and the website is the secondary user. The inventory availability shown on the website as customer orders can be an online real-time integration. Or it can be uploaded periodically through an interface (e.g., hourly with updated product totals). When you look at integrations, each type of transaction becomes an integration point.

Vendors have developed standard data mappings between commonly used applications in the multichannel industry. Some examples: OMS and Inventory Forecasting Systems (e.g., Direct Tech); WMS (e.g., Manhattan & Associates or Red Prairie); vendor drop ship (e.g., VendorNet); credit processors (e.g., Chase or Litle & Co.); OMS data conversion between systems and business intelligence tools (e.g., Taurus Software).

Here’s how to develop requirements:

Determine what data will be exchanged between the proposed systems at a subsystem and data field level. Start by developing a high-level data flow diagram of the prospective interfaces between systems. A simple example would be exchanging products’ SKU demand, sales, returns, cancellations, purchase orders, receipts, inventory adjustments, etc. between the forecasting system and OMS.

Then take each transaction to lower and lower levels of detail design. Develop the data field attributes for transactions from the OMS to the Inventory systems. Ultimately, this process will give you detailed requirements for your design document to discuss with vendors.

What direction does the data flow in between systems?

What is the frequency and schedule of the data availability? Will the data need to be online, real-time, scheduled batch, or quasi-on-line?

Do the vendors have thoroughly documented Application Program Interfaces (APIs) to design your data mapping and programming? Does the vendor have a similar interface or module interfaced with other systems that can be modified for your use?

Ensure all your research gets documented and signed off by your staff and the vendors’ integration team.

For larger projects with dozens of interfaces, you may be able to justify licensing software tools that ease the initial programming and maintenance of interfaces.

Systems testing between a critical online provider (e.g. credit processor) and your OMS, you may have to schedule one or more tests and receive their certification or sign-off before putting them into production.

If you don’t have the internal skills to take on the necessary interface/integration, it’s a good way to use consultants or the vendor’s analysis on a contract basis. Remember, the “devil is in the details”. The more diligent your research, the more accurate the time, cost, and schedule estimates.

OMS Development Challenges

It makes sense to immediately present the nuances of using the order processing system in general. This will avoid unpleasant incidents during the operation of the system.

Adaptation of the system to the company's processes

The system should adapt to the sales process, not sales to the system.

It is the process of selling and processing an order that can be a competitive advantage for a company. It would be wrong to break your process for the sake of some system.

If the system is inflexible and difficult to change, then any innovation in the order processing process will be stifled. The system should allow quick adaptation to changing business realities.

What changes could these be?

- introduction of a new stage in the order life cycle;

- introducing a new role into the system;

- adding new information to the order;

- providing the client with additional opportunities in his account;

- integration with client software systems, etc.

Work on different devices of the order accounting system

It is essential to access information in the system quickly. From the phone, in the country, in the car, maybe in a stuck elevator.

This will allow you to quickly manage certain processes and make adjustments.

If the system works through a browser over the Internet, then it is available almost everywhere and always. This gives you the ability to be physically located anywhere and maintain operational communication with the entire business system.

Notifications

How flexible can you manage notifications? Where can they come? Is it possible to remove unnecessary notifications? All these are crucial questions because, with a huge flow of unnecessary notifications, you stop responding to them.

Notifications should be a trigger for some action and not turn into action in itself - "So, now I need to sort out a pile of notifications that no one needs." Creating the right notifications is an iterative process. As you use the system, you will come up with more and more subtle cases when you need notifications.

It is important to know at the beginning of the system creation that you will be able to create very flexible notifications that will be made for specific situations in the order processing process.

Access levels in the system

Each employee should have everything necessary for work, but nothing more.

Extra access increases business risk. If a person works only with order A, then he does not need to know anything about order B. The sales manager can know everything about sales, but you do not need to give him information about production details.

It should be possible to fine-tune access.

In the Falcon Space system, this is done through roles + at the level of prescribing access to an object for a specific user in SQL. This allows you to set access control for people working in the system very flexibly.

Operation speed and system performance

If the system slows down, it is very annoying for the user. When working with the system, a person should overlook the download details. He should be focused on the business process and not be angry that the page takes a long time to load the report.

When the system works quickly, the user develops a certain rhythm of work, reducing the number of distractions, which increases human productivity.

Simplicity, clarity, and error protection

Evaluate the convenience of working with the system. An inconvenient, incomprehensible system will provoke the user to make mistakes. The system should guide the user to achieve the desired goals and not be an obstacle.

In difficult places, the system should prompt the user on what to do, what to enter, in what format, and at what stage of the process he is.

Keep the system interface as simple as possible (over time, it will still become complex due to new implementations). This will lower the entry threshold for system users and reduce the number of operator errors.

Time Cost Minimization

The system should allow for finding time costs. It is not just a data-tracking tool but a time-tracking tool.

Any business is a movement from status to status. The faster this movement - the more we can perform operations per day, week, or month.

It is important to reduce this time interval between statuses. To reduce it, it must be fixed and measured. Then, analyze and make a management decision.

The order processing system should allow fixing any time intervals when any object's state (order, warehouse request, project stage, etc.) changes. Not a single ready-made boxed system can give this by default. This is your unique experience and way of dealing with time costs specific to your order processing business process.

Metrics and performance indicators of the order control system

The default metrics in the system are not good. In the course of work, there will be a need to obtain narrow, non-trivial metrics, which most likely will not be among the initial set.

It is important to be able to collect all the necessary data regarding the work on orders and be able to make analytical reports on this data.

How Much Does It Cost to Build a Custom Order Management System?

Depending on the requirements, an OMS usually costs about $60,000 - $100,000 to build. However, the total cost can be as low as $40,000 or as high as $150,000. An OMS with fewer features (also known as a "minimum viable product" or MVP) will be more affordable than an app that includes all intended functionality.

How Ardas Can Help You?

Consider implementing an order processing system not as an expense but as a strategic investment, as an improvement in the order management system. The system will eventually work as a conveyor for the movement of orders.

The system must be built for processes and not vice versa. The business will change, and the system must keep up with it. Ideal for such a process:

- When everyone knows exactly what to do, how to do it, and when to do it.

- When there are no delays, and the order goes through all the stages from New to Closed very quickly.

- When the customer is satisfied and ready to recommend your service.

- When any anomalies and deviations can be immediately tracked, and the cause of their occurrence can be found.

- When the client can do many operations on order on their own, thereby reducing the load on your resources.

The ideal is hard to come by. This becomes impossible if you use a rigid, impossible or difficult-to-change system. Move iteratively towards your ideal order process.

Start with a description of the project concept: what features will be in the system, what roles will there be, and what will be the order's life cycle. This will be the starting point for creating your order management system. The best part of any article is to remind you that Ardas can develop a SaaS courier-based system for your business. We are waiting for your applications!