Warehouse Management System (WMS) Development: How to Create Own Custom WMS for Logistics

Business processes in the warehouse - accounting for goods, storage and movement, collection of orders and preparation of kits for shipment, and inventory - all of them lose control if they are not sufficiently automated.

And the larger the warehouse and the wider the range of goods, the less effective manual control becomes - the likelihood of errors, delays and losses increases.

Practice shows that implementing the Warehouse Management System (WMS) can significantly increase the speed of the warehouse, reduce the number of errors, minimize the impact of the human factor, etc. Warehousing without WMS today is impossible to imagine.

Why Do You Need Warehouse Management Software?

The warehouse is a key link in the logistics structure of any modern enterprise. Implementing systems such as WMS or other LMS for the logistics industry, including programs for the warehouse, allows you to optimize warehouse space and speed up the formation of orders of any volume. With their help, the manager receives accurate information about the location of a particular product and manages the movement of goods, even with limited expiration dates.

But the warehouse WMS system can quickly and accurately perform not only the above tasks. Automatic identification of products, control over the execution of tasks, a strategy for placing new arrivals and other functions are also included in the "responsibility area" of the WMS software.

What tasks does the WMS warehouse program solve?

"Warehouse management" includes a more extensive list of tasks than "warehouse accounting". If, in the second case, it means control over the balance of products in the warehouse and the preparation of shipping documentation, then in the first case, it means, at a minimum, the automatic identification of goods and new arrivals.

The WMS program is a part of the warehouse management system aimed at solving most typical tasks without the participation of company employees:

Product identification

Depending on the characteristics of the product group, the identifiers are the date of manufacture, expiration date, product name, information about the manufacturer, and much more. WMS can store and control all or only some of these parameters.

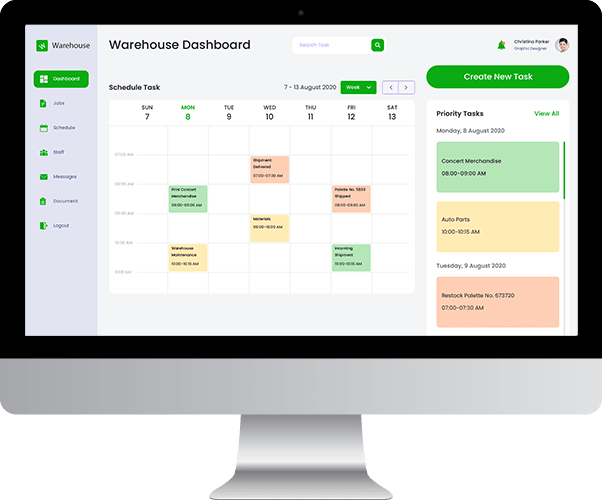

Setting tasks and monitoring their implementation

Placement of goods in cells, movement of goods, collection of shipments - all this is controlled by WMS. The program automatically generates tasks and fixes the time of their execution. In addition to control, it allows you to get complete statistics on each employee's work speed and the average time spent on completing a particular task.

Dispatching

When automatically distributing current tasks between warehouse workers, the employees' location, the priority of each task assigned, and other work features are taken into account. This ensures a uniform load on the staff and the warehouse space itself, helping to avoid collisions during shipment, placement or movement of products.

Development of a product placement strategy

Depending on the class of the BMC program used for the warehouse, it can automatically divide goods into predefined groups or allow you to enter hundreds of new rules for product placement manually.

Formation of shipments

The software part of the system "knows how" to distribute tasks by dispatch zones, group boxes and trays, and pick-up containers. In addition, before the transfer of tasks to the contractor, WMS automatically accepts applications, processes them and reserves products concerning a specific warehouse area. In this case, you must ensure the order management software system works very accurately.

Principles of operation of the WMS warehouse system

WMS systems include not only the use of specialized programs for the warehouse but also the use of certain equipment. The main component of the hardware is DCTs (data collection terminals) that recognize QR codes and RFID tags (if any are used to label goods stored in a warehouse). In addition, the used DCT must have a permanent connection with the server to transmit information about ongoing operations and scanned codes (barcodes, QR codes, etc.). WMS-system, or rather its software part, conducts further analytics based on the information received from the terminals.

The architecture of such a warehouse program is built as follows:

- The interface is that part of the application with which the user interacts (enters data, prescribes the necessary actions, etc.).

- Database - all information that is stored on the server. The program accesses it when user requests arrive.

- Business logic - subroutines that contain algorithms for processing client requests and solving typical warehouse automation tasks.

Pros & Cons of an Off-The-Shelf WMS

Off-the-shelf products are often used by businesses that are new to automation and are not ready to invest in custom products. At first glance, an off-the-shelf management system might not seem advantageous. It comes with its own pros.

- Quick to deploy. It takes 10-15 minutes to register an account and set up a subscription for an off-the-shelf tool. In the span of several days, the entire team can learn how to use the tool. As a result, the return on investment comes quicker than custom products.

- Large user community. Widespread off-the-shelf management systems have a large user base, that’ll share tips, maintenance hacks, and so on. This way, you will always find someone willing to answer a tool-related question.

- Lower initial cost. In case you want to test if the idea of a WMS implementation is viable, subscribing to a basic off-the-shelf tool is the safest choice.

Despite its low cost and other benefits, an off-the-shelf warehouse management system doesn’t lack drawbacks. Let’s examine the most common ones:

- Such systems often require additional components. An off-the-shelf warehouse management system will likely lack a few features needed to manage your business efficiently. In this case, you’ll still have to hire a developer to upgrade the tool, increasing its overall cost.

- Subscription costs add up over time. If you want to create and use a warehouse management system for years, the initial low cost of an off-the-shelf solution will nullify itself. Over time, the business manager will spend more paying for subscriptions than developing a custom tool.

Pros & Cons of a Custom WMS

An off-the-shelf product can create functional constraints that will halt your company’s development. This is not the case for companies that make digital freight management software from scratch that provides warehouse managers with the necessary tools, flexibility, and freedom.

The advantages of a custom WMS include:

- A business owner can ask for integration with all the tools needed for peak efficiency;

- A warehouse manager will only have the features they need for handling mundane activities instead of having to deal with an interface cluttered by seldom-used tools;

- Constant support on a developer’s end;

- Personalized security measures as opposed to generic ones used by off-the-shelf products.

There are certain challenges when it comes to custom software. The main disadvantages that restrain warehouse managers from using tools built by dedicated teams include:

- A significant reliance on the team’s skill;

- Inability to read user reviews about the exact WMS a business manager wants to develop;

- It will take more time to build WMS software than to deploy an existing tool;

- Higher initial development cost means a custom WMS only pays of as a long-term investment, not a quick fix.

In short, an off-the-shelf solution is a better fit for a business if it:

- Doesn’t run multi-layered, advanced operations;

- Is new to automation and a manager wants to start warehouse management solutions usage;

- Needs a quick fix;

- Operates on a limited budget.

In other cases, a custom WMS appears more attractive due to more flexibility and scalability opportunities and its lower cost in the long run.

WMS software development with Ardas

We develop warehouse IT systems that allow you to increase operating profitability, automate unique business processes that are not provided for in standard solutions, implement complex integration with the equipment and software used by other services, and ensure maximum performance and stability.

You can get it all in one as in SaaS-based courier software or order custom logistics software development.

Examples of business development models where custom development is profitable

When a company discovers bottlenecks in warehouse automation that force employees to waste time and effort regularly, it becomes possible to analyze unnecessary labor costs that do not create value. This figure is scaled by the number of employees and operations performed, and can represent a significant burden on the business, justifying the development of an IT system that considers all individual characteristics.

Ability to build unique business processes

A custom-built WMS allows you to digitize workflows without compromising the limitations of a third-party solution and build optimal functionality to increase efficiency based on experience.

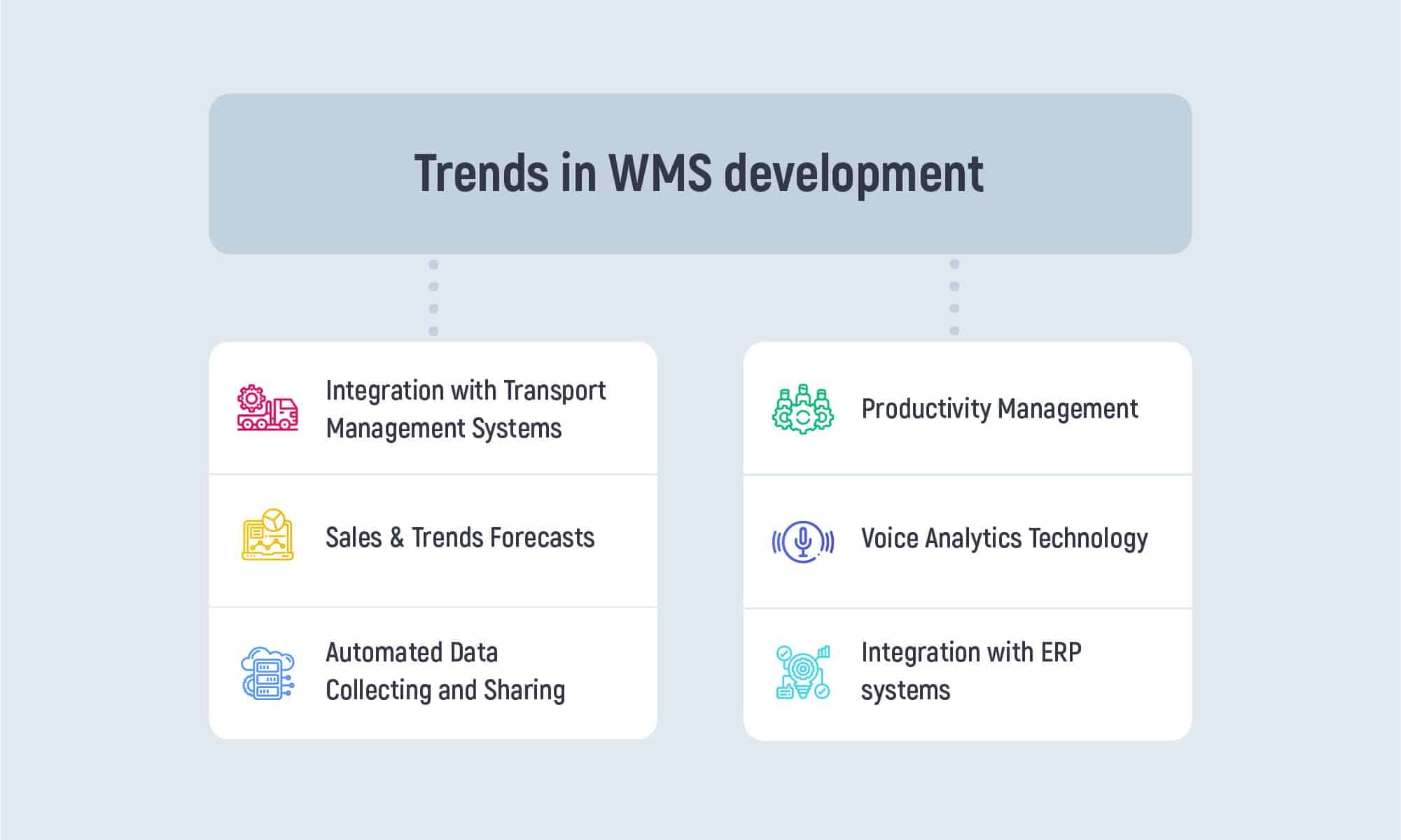

Comprehensive integration with other IT systems and services

Often, standard systems have limited integration options, while a business, as it develops, “acquires” the most diverse package of services. WMS development helps to bring order to the data and create a unified information environment.

Foundation for development

Own WMS allows you not to limit the evolution of your business processes and not to adjust them to a pre-installed template, which creates space for development and search for unique advantages.

Productivity increase

Universal solutions drag behind them the baggage of functionality that is not in demand at a particular enterprise, which does not positively affect overall performance. Building your own system, taking into account the architecture and specifics of the business, can level out uneven load distribution and increase productivity.

Choose the right partner to build a powerful WMS

The supply chain is a fundamental part of your company’s logistical health. With this in mind, it’s crucial to understand the ways you can improve it to keep up with demand, drive warehouse management performance, deal with shipping issues, and become an outranking player in the market of competitors. The following recommendations can help you operate your supply chain better:

- Analyze your business operations and decide whether you need full-featured WMS software or a more specific solution for efficient inventory management.

- Learn common inventory management techniques, choose what suits you best, and apply them.

- Organize your warehouse design to have a frictionless working process.

- Adopt emTechs (emerging technologies) to bring more automation. Despite being expensive, the advanced techs increase overall productivity and pay back in the long-term perspective.

- Consult a trusted custom software development provider to find the perfect solution for your business. Cooperation with professionals in designing supply chain software can help minimize the risks of huge unjustified investments.

If you are ready to transform your inventory management system or build a new solution from zero, contact Ardas representatives to get in-depth expertise.