Supply Chain Technology Trends To Watch in 2022

We like to periodically collect reviews on the hottest developments in various fields. So, we recently discussed SaaS industry trends and current trends in finance industry. Now it is time to check the latest trends in supply chain management.

Today, the meaning of supply chains has expanded beyond the classical physical flows of goods to include the activities and processes associated with the management of relationships, information and financial flows that support physical flows. Supply chains have become a source of innovation for most, if not all, businesses these days.

This year has drastically changed supply chain processes around the world. Some innovations will be with us in 2023, some will not. So, what to expect in 2023 in the supply chain industry? What new supply chain software trends will we discover and how can we prepare for them? Should we follow the latest trends or is it better to stick to old strategies? These and many other questions are highlighted in this article.

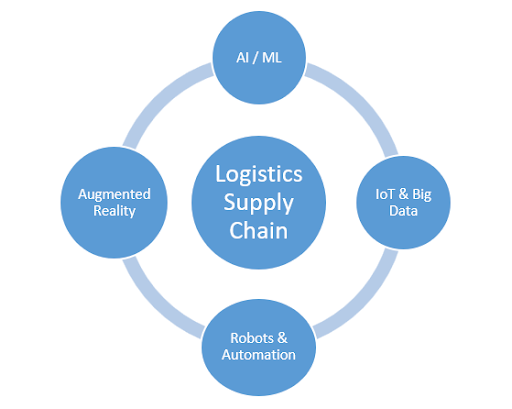

How Digital Technologies Are Changing Supply Chains

To make accurate decisions, managers need access to real-time supply chain data. But outdated technologies sometimes hinder its transparency at all stages. However, things may change soon.

Perhaps in 5–10 years a well-functioning, self-regulating system will appear that will ensure the optimal execution of all work processes and require minimal human intervention.

Digital technologies will help companies collect, analyze, integrate and interpret high-quality real-time data. Automation, forecasting, robotization will be built on this data - all the innovations that will replace traditional supply chain management.

Robots and AI

Leading companies are already using robots and artificial intelligence to digitize and automate time-consuming and repetitive processes such as purchasing, invoicing, debt settlement, and partly for customer service. Predictive analytics help you better predict demand, helping companies improve asset utilization and deliver customer convenience at the best price.

Sensors that capture the condition of machines in use allow for more accurate predictions about the possible timing of failure, and this reduces downtime. Blockchain has launched a revolution in the interaction of participants in flexible supply chains. Robots increase the productivity and profitability of warehouses and fulfillment centers. Courier drones and self-driving delivery vehicles are no longer a fantasy.

Digital Control Center

The key concept is the digital control center. It is a virtual decision-making center providing up-to-date and complete information about global supply chains. For leading retailers, these control centers have become a kind of brain that regulates their activities. Typically, such a center is the office of the data analysis team. The team monitors what is happening around the clock on multiple high-definition screens that display real-time information and 3D images for every link in the supply chain (from order to delivery).

Visual signals provide early warning of shortages or other difficulties. And front-line employees can correct actions before potential problems become real. The digital center is based on real-time data transmission, unconditional accuracy, absolute focus on the client, verified processes and an analytical leadership style.

Tech vs. People Force

The trend is clear: in supply chain management, technology replaces people and works more efficiently. In the future, automated processes, advanced analytics, sensors, robots, artificial intelligence and a continuous learning cycle will minimize the need for human intervention. But will there be work left for supply chain managers when planning, purchasing, manufacturing, order fulfillment, and logistics are automated?

Leaders in this field will soon have to switch from managing the people who perform the routine tasks of supporting operations to managing information and material flows with the involvement of a limited number of specialists. The demand for supply chain analysts who can structure and validate data, use digital tools and algorithms, and make accurate forecasts will soon grow.

Going even further, it will require specialists who will develop the technical "engine" of the supply chain to support the constantly changing strategies and priorities of the company. They will be assisted by a small number of specially hired or trained employees who perform tasks at the interface of operations and technologies.

Because no one has the skills needed for new roles today, the biggest challenge for companies is to understand the supply chain of the future and develop a strategy to find the right people for these important roles.

Top 10 Supply Chain Technology Trends

Supply chain management is by far one of the most important functions of a company's strategic management. In this regard, more and more enterprises are turning to digital management technologies in order to reshape their supply chains in accordance with changing market requirements.

The concept of "Industry 4.0" was first introduced by the German federal government as a strategic plan for the development of German industry, based on the unification of industrial equipment and information systems in a single information space, which will allow them to interact with each other and with the external environment without human intervention. The numbers "4.0" mean that this direction of industrial development has such a great potential that it will inevitably lead to the fourth industrial (industrial) revolution.

So, let's consider the key supply chain trends to watch for in 2023 within the “Industry 4.0” concept.

Trend 1. AI in Logistics

Over the past few years, the logistics industry has begun to integrate AI-based solutions into its operations, including intelligent transportation, route planning, and demand planning, but this is just the beginning. From last-mile delivery robots and sustainability solutions to automated warehouse picking systems and predictive optimization software, artificial intelligence is already making a huge difference in logistics.

Research shows that 40% of logistics business owners believe that AI improves inventory management through the ability to create smarter production and distribution centers. Artificial intelligence understands the complex dynamics of inventory control in real time.

This technology can also predict scenarios, recommend actions and make the right decisions. Therefore, in 2023, the implementation of artificial intelligence solutions, especially in combination with IoT, will be one of the most crucial supply chain trends.

Takeaways

- AI-based solutions provide wide functionality for operation automatization, route planning and warehouse management.

- AI improves inventory management.

- AI is an integral part of IoT and the Industry 4.0 concept.

Trend 2. Augmented Intelligence

Along with AI, the use of augmented intelligence is also expected to grow. Augmented Intelligence combines human intelligence with automated AI processes.

Experts predict that the augmented intelligence market will reach more than $54 billion by 2026, from approximately $18 billion in 2022. This is due to the growing amount of complex business data, which requires using advanced tools and analytics, including in the field of logistics. This is also one of the main supply chain management trends.

So, logistics companies can be expected to implement more augmented intelligence solutions that ultimately enable logistics professionals to complete their jobs faster, reducing errors and delivering cost savings.

Takeaways

- Augmented Intelligence combines human intelligence with automated AI processes.

- Augmented Intelligence is critical for advanced business data analysis and, therefore, risk management.

Trend 3. Internet of Things

The Internet of Things or IoT is a network of physical devices/things connected by wireless connection, making them available for control anywhere, anytime, from any location. This is an independent automated ecosystem and a unique concept of the organization of manufacturing and business, which is a real discovery of the last decades.

According to statistics, the global IoT in the logistics market was estimated at more than $37 billion in 2021 and is projected to reach $93 billion by 2028.

As one of the most mind-blowing supply chain technology trends, IoT does not just help to create an effective network of devices to automate processes. It is also a way of adopting or integrating other technologies. For example, transport sensors can collect information for further analysis of logistics data with the help of AI, creation of logistics routes or schedules based on the results, planning and even risk management.

IoT is also a component of increasing supply chain visibility, which we will discuss later. It is used to track cargo movement, inventory management and predictive maintenance.

Takeaways

- The Internet of Things, or IoT, is a network of physical devices connected to one ecosystem.

- AI is an integral part of IoT and the Industry 4.0 concept.

Trend 4. Real-time Supply Chain Visibility

Supply chain visibility (SCV) is no longer just a great thing for logistics companies, in 2023, it is a must, and in the coming years, it is necessary to take it one step further - to become real-time. This real-time data is now more in demand by customers and carriers than ever, meaning that logistics and supply chain businesses need to focus on implementing advanced SCV solutions into their operations.

Emerging supply chain visibility startups are providing technology that facilitates rapid response to change by enabling companies to leverage real-time data. Such data includes traffic patterns, weather, or road and port conditions that are used to take action and change demand or redirect supply and optimize routes.

Logistics companies using fully integrated supply chains are now reportedly seeing 20% more efficient than those without integration. So SCV is one of the most critical supply chain trends.

Takeaways

- SCV provides full transparency to customers improving logistics brand credibility and reputation.

- SCV is all about collecting data in real-time not only to control the delivery process but also to use it for business analysis, route optimization and risk management.

Trend 5. Blockchain as a Supply Chain Industry Trend

According to the study, the global blockchain technology in the supply chain management market was estimated at more than $262 million in 2021 and will grow to $3153.7 million by 2028. This is another critical future trend in supply chain management for several reasons.

-

Blockchain provides better visibility and traceability.

-

This facilitates access to financing and improves the coordination of funds, simplifying international financial operations.

-

This technology makes it easy to track the history of a product from the point of origin to the final point of delivery.

Blockchain implementation helps reduce human errors, adopt IoT technologies faster, and automate the financial side of supply chain management. It is also essential to ensure the security of transactions.

Moreover, synchronizing with partners and using a shared blockchain helps to synchronize valuable logistics data, track shipments and automate payments without significant changes to systems, exchanging only the most relevant data.

Takeaways

- Blockchain is an essential part of IoT.

- This technology helps control all financial operations and provides top-notch security tools.

- Blockchain implementation helps reduce human errors and automate the financial side of supply chain management.

Trend 6. More Focus on Last-Mile Delivery

Demand for last-mile delivery and its market is soaring and is anticipated to grow by 78% globally by 2030, as per the Economic Forum. Since the COVID-19 pandemic, an enormous inflow of home deliveries has resulted in businesses adding more emphasis to their last-mile deliveries.

With last-mile delivery costs contributing to over 50% of total shipping costs, the rising expectations of in-home delivery increase the danger of encountering inefficiencies. Many businesses have started to adopt last-mile delivery technologies into their logistics operations and this trend will increase in 2023.

Takeaways

- Last-mile delivery costs are 50% of total shipping costs.

- Improving this princess is crucial, so in 2023 logistics businesses will focus on searching for a better way of last-mile delivery optimization.

Trend 7. Amplification of Cybersecurity for Data Protection

Cybersecurity is critical to protecting networks from cyberattacks, which be a dominant threat to supply chains worldwide. The explosion of information and data-driven organizations is creating more areas of vulnerability. This interconnection means supply chain partners can accidentally expose one another and their customers to privacy breaches, fraud and worse.

Cybersecurity is one of the most critical current trends in supply chain management. 38% of logistics companies have significant security holes and unresolved data privacy and security issues.

Expect greater collaboration when safeguarding networks, devices, people and programs in 2023. Companies will emphasize bringing cybersecurity beyond just their corporate IT systems into their factories and warehouses’ operational technology (OT) environments this year. Additionally, more organizations will favor investing in redundancy, firewalls, advanced anti-hacking technologies, and employee training.

Takeaways

- Cybersecurity is critical to protecting supply chain network from cyberattacks.

- 38% of logistics companies have significant security holes and unresolved data privacy and security issues .

Trend 8. Increased Automation to Cut Back Manual Tasks

Almost every link within the supply chain, ranging from booking to settlement, can enjoy some sort of automation within the system. At a high level, automating manual tasks allows companies to reduce manpower, freeing up teams to specialize in high-level strategic work and productivity instead of repetitive tasks.

Specifically, time-consuming methods, including setting appointments, checking shipment status, and generating invoices, will be automated, which will allow companies to handle the next volume of shipments more efficiently. Also, manual errors and leakages will be avoided if repetitive, tedious, yet crucial operations are automated.

Takeaways

- Automating work processes saves money by minimizing human errors and speeding up data processing.

- Automation is an indispensable part of Industry 4.0.

- Automation is an indispensable part of Industry 4.0.

Trend 9. Circular Supply Chains

Our top of supply chain management trends includes replacing linear supply chains with circular ones. What is the essence of such an approach? The cost of raw materials is constantly increasing, and their availability is constantly changing, so many companies are looking for solutions to resell discarded products or turn them back into raw materials.

It is also worth noting that the strict requirements for waste disposal require suppliers to seek ways to operate ecologically more actively. And a circular supply chain is a way out of the situation. It helps reduce disposal costs and balance the risk of fluctuating prices for raw materials.

Takeaways

- Circular supply chains are about an ecological approach to business.

- They help save money on waste disposal.

- Circular chains are a way to comply with complex regulatory requirements.

Trend 10. Cloud-Based Solutions

Cloud solutions play a crucial role in logistics. They help automate the process of processing orders and optimize the process of managing them. Also, with their help, you can use relevant data in real-time, optimize delivery routes, implement state-of-the-art warehouse management systems and provide a system for protecting sensitive data.

Statistics show that by the beginning of 2022, 50% of logistics service providers were already using cloud solutions, and 20% were ready to move their on-premise solutions to the cloud. So, the growth of demand for implementing cloud solutions and cooperation in the SaaS model is one of the most obvious predictions for supply chains for 2023.

Takeaways

- Cloud solutions are an important part of Industry 4.0. They are indispensable for storing and processing large amounts of data.

- Logistics companies have to move forward to cloud services if they want to be competitive and implement other technologies, such as AI or real-time cargo tracking.

What Ardas Knows About Trends in Supply Chain

We have already mentioned more than once that the Ukrainian IT industry has long been a leader in the market for high-quality development services. In particular, our company has almost 20 years of experience in developing various tools for the logistics business.

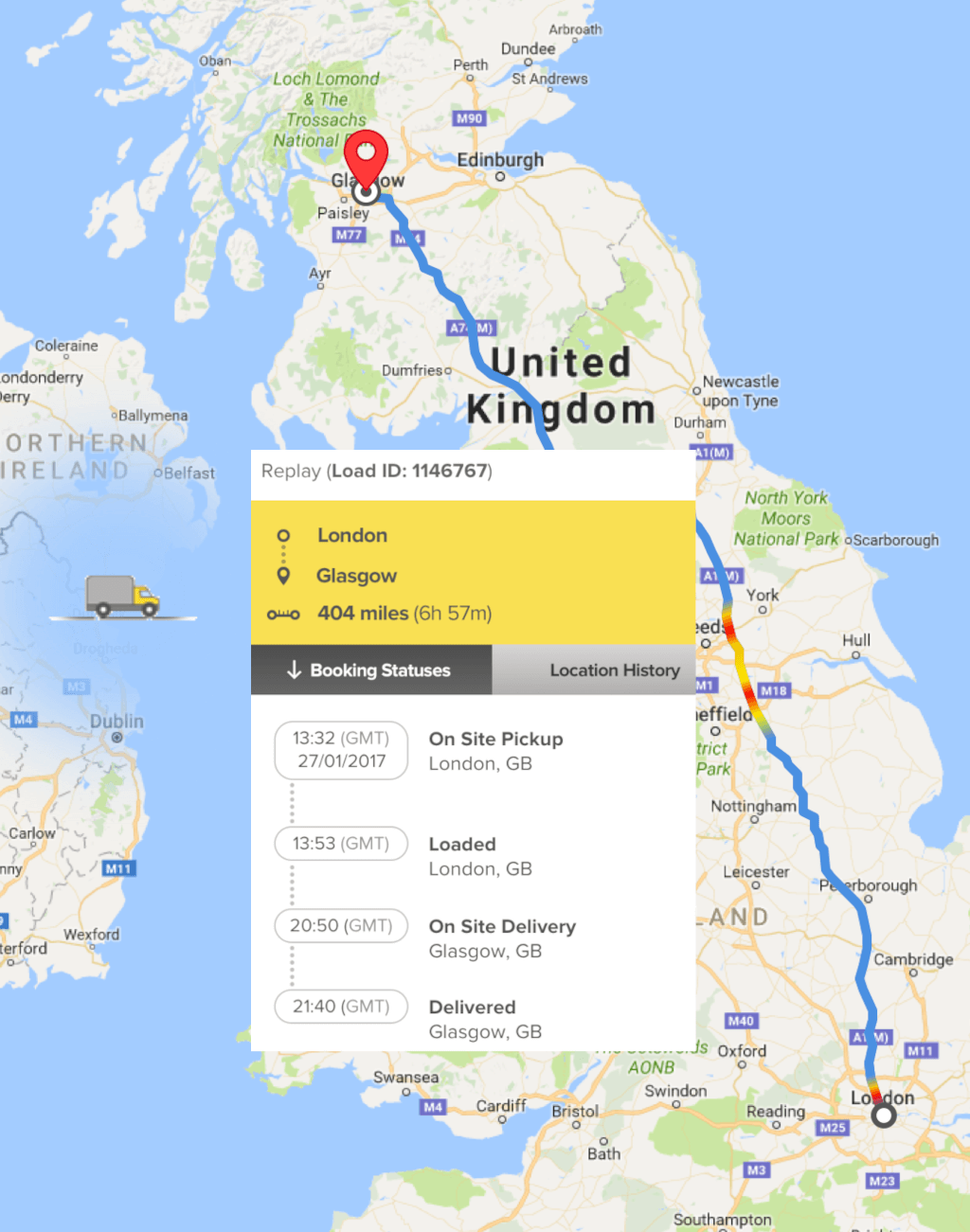

One of our most successful projects - shipment tracking software. It serves the entire flow from posting the load to its final delivery helping transportation companies and individuals to do their work with ease.

Naturally, most of the functions developed in this system are made for the convenience of supply chain management.

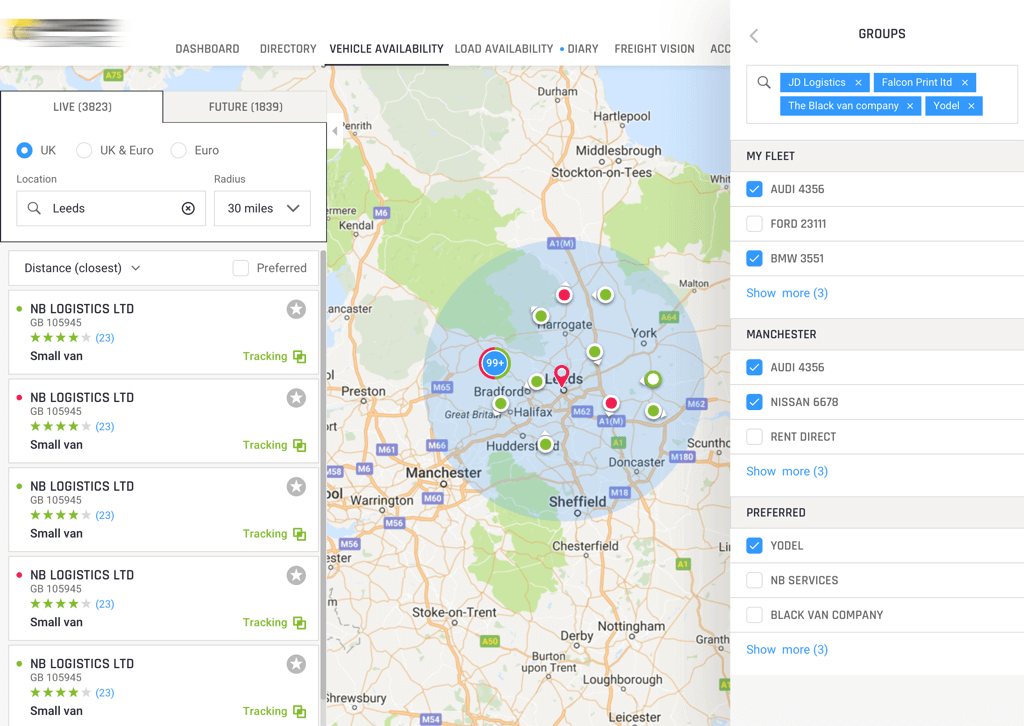

The whole set of fleet and load tracking features were implemented for couriers and customers. The platform tracks all vehicles and loads and visualizes them on the map using 15+ TMS providers or GPS vehicle tracking system. The map shows current loads with destinations and available transport with movement direction. Delivery ETAs, delays, fleet and load statuses, route history are displayed and updated on the fly. All map visualization and geocoding were initially done with Google Maps and now changed to Here WeGo.Courier companies can add their drivers and vehicles. A simplified UI was done for individual drivers with only one car. The courier manager can post jobs to subcontract a driver.

Fleet real-time management is done with a web or mobile app and telematics integration systems.

Couriers can filter loads by many parameters such as vehicle type, region/area, etc., expose their availability, look for the closest loads, apply for a job by sending a quote, communicate with customers using an external communication tool.

The main driver app including its regional versions allows users to receive the tasks, track their progress, send messages, etc. It is available on iOS and Android, originally developed natively and now it is been redeveloped on Flutter.

The application for the SaaS allows managing the loads from managers' and dispatchers' points of view. It also includes a live availability map that shows the fleet capacity in real-time and an instant messenger with specific B2B features.

What Is the ROI for Supply Chain Technologies?

As with any type of investment, companies are concerned that adopting supply chain technologies may not be worth the risk. However, 100 percent of respondents to the Jabil survey report that they’ve already reaped benefits from their supply chain technology investments:

- 57 percent of the respondents said their companies are enjoying ongoing cost reductions.

- 51 percent noted that their companies’ technology investments improved their internal and external collaboration.

- 46 percent experienced increased visibility and transparency.

- 40 percent said they were able to respond to changes in demand more quickly.

- 40 percent recognized improved customer experiences.

- 32 percent reduced supply chain risks.

- 30 percent have been able to decrease time-to-market.

When it comes to company size, larger companies, or those with more than $1 billion in annual revenue, have gleaned larger returns on investments than smaller companies. These can be attributed to economies of scale as well as the securities of more established infrastructures and processes at larger companies. However, this should not stop smaller companies from investing, because they can and are experiencing the benefits of these technologies too.

For example, nearly half of companies with less than $1 billion in revenue experienced ongoing cost savings. In addition, smaller companies were more likely than large companies to report an improved customer experience because of their supply chain technology investments. The caveat is that smaller companies will need to conduct deeper evaluations of supply chain technologies to determine which will have the greatest impact on their operations and offer the largest return on investment given their business structures.

The bottom line is that the rate of technological advancement is accelerating, and survival, regardless of company size, will depend on keeping up with and connecting to the developing supply chain ecosystem. It is important for companies to carefully evaluate potential supply chain technology options and allocate funds to help their businesses evolve with the changing times.

Let’s Implement Supply Chain Trends 2023 in Your Business

Enhancing the supply chain through technology can help improve the processes and perhaps even help build a symbiotic relationship with the customers. In times of pandemic, technology can make a difference in being able to conduct logistics operations successfully. Ardas is helping adopt a broad and holistic perspective when applying technology for data mining, visibility tools, autonomous transportation, and enhancing customer retention.